Okay, here’s my attempt at a blog post, following your instructions and example:

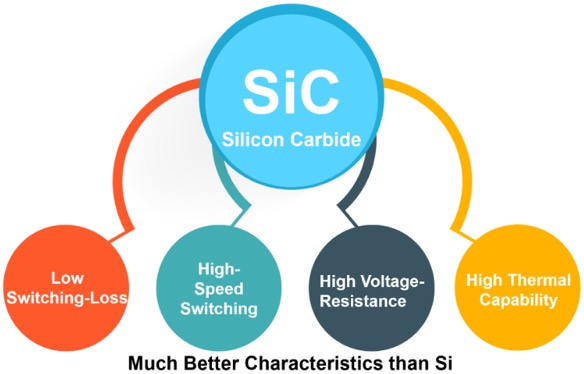

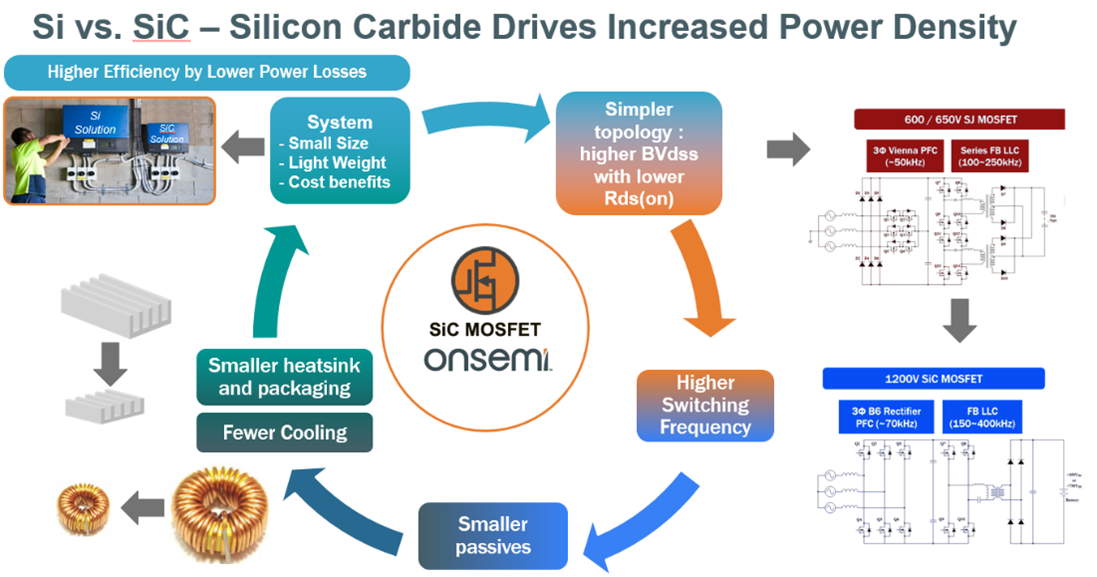

So, I’ve been messing around with these things called “silicon carbide MOSFETs” – SiC MOSFETs for short. I kept hearing about how they’re, like, way better than regular silicon MOSFETs, especially for stuff that needs to switch really fast and handle a lot of power. Think electric cars, solar inverters, that kind of thing.

I decided I needed to see this magic for myself. I ordered a few different SiC MOSFETs from some online place. I gotta say, holding them in my hand, they didn’t look any different. Little black squares with metal legs, just like the silicon ones I’m used to.

Getting Started, Blowing Stuff Up

First thing I did? Hooked one up to a basic test circuit. Just a power supply, a resistor, and the MOSFET. I wanted to see how quickly it could switch on and off. The datasheet said it could do it in nanoseconds – nanoseconds! That’s crazy fast.

I used my oscilloscope, carefully connect them.

Of course, I blew up the first one. Classic me. Turns out, I’d underestimated how fast those things switch. My gate driver – the thing that tells the MOSFET when to turn on and off – wasn’t fast enough. It was like trying to open and close a door super fast with a rusty hinge. The MOSFET got confused, got too hot, and… poof. Lesson learned: gate drivers are important.

The Right Tools for the Job

I did some more digging, figured out I needed a gate driver specifically designed for SiC MOSFETs. They’re a different breed. They need higher voltage swings and faster rise/fall times. I got my hands on a dedicated SiC MOSFET gate driver, a little board with a bunch of components on it.

Testing, Testing, 1, 2, 3

With the new gate driver, things got much smoother. I set up the same test circuit, this time being extra careful with my connections. I double-checked everything, made sure my power supply was set right, and held my breath.

I fired it up, and… wow. The switching speed was incredible. On the oscilloscope, the signal was almost a perfect square wave. It was switching on and off so much faster than the silicon MOSFETs I’d used before. I use the signal generator to adjust the input switching frequncy, and I found it could reach a very high frequency!

Efficiency Gains – Real or Hype?

Next, I wanted to test the efficiency. Supposedly, SiC MOSFETs have lower on-resistance (meaning less energy wasted as heat when they’re on) and lower switching losses (less energy wasted during the on/off transitions). This is a BIG deal for things like power supplies, where even a small efficiency improvement can make a huge difference.

I built a simple buck converter circuit – a common type of DC-DC converter. I tested it with both a silicon MOSFET and a SiC MOSFET, keeping everything else the same. I measured the input voltage, input current, output voltage, and output current. Then, some basic math to calculate the efficiency (output power divided by input power).

The results? The SiC MOSFET converter was noticeably more efficient. Not by a huge amount, but definitely a few percentage points. That might not sound like much, but in the world of power electronics, it’s significant. This is very exciting!

My Takeaway

- SiC MOSFETs are fast. Really, really fast. You need a good gate driver to take advantage of that speed.

- They’re more efficient. Less energy wasted as heat.

- They’re a bit more complicated to work with. Gate driver selection is crucial, and you need to pay attention to layout and thermal management.

My little experiment confirmed what I’d read: SiC MOSFETs are pretty awesome. They’re not going to replace silicon MOSFETs overnight, but for high-power, high-frequency applications, they’re definitely a game-changer. I’m excited to see what else I can do with them. Maybe a more powerful motor controller next?