So, I wanted to share a bit about my journey with MOSFET wiring. It wasn’t something I got right off the bat, let me tell you. For a while there, I was just staring at these little three-legged things, wondering what the heck I was supposed to do with them. I was trying to control some beefier stuff than my little microcontroller could handle directly, you know, like a string of LEDs that pulled a bit of current, or a small motor. My usual transistors were either getting too hot or just weren’t cutting it.

Figuring Out the Basics

My first few attempts were, well, let’s just say a bit smoky. I think I treated them like regular bipolar junction transistors at first, and that was mistake number one. I’d look at datasheets, and they were just a bunch of numbers and graphs that didn’t make a whole lot of sense to a guy like me just trying to get something to turn on and off.

The big breakthrough for me was understanding the three pins: Gate, Drain, and Source. Once I got that clear in my head, things started to click. I spent a good afternoon just looking up diagrams for common N-channel MOSFETs, the kind I use most often. I’d physically take the MOSFET, look at its part number, and then search for “pinout” for that specific one. That helped a ton.

My Usual Hookup Process

Okay, so here’s how I generally go about it now, after a bit of trial and (expensive) error.

First, I always double-check those pins. Seriously, I still do. Get Gate, Drain, and Source mixed up, and you’re gonna have a bad time. I usually grab my breadboard for testing.

Then, I think about what I’m trying to control – let’s say it’s a small 12V motor.

- The Drain pin, that’s where I connect one side of my motor. Usually, it’s the negative lead of the motor if I’m switching the low side.

- The other side of the motor (the positive lead) goes straight to my 12V power supply positive terminal.

- The Source pin of the MOSFET, that one I connect to the ground of my 12V power supply. And also, very importantly, to the ground of my microcontroller (like my Arduino or ESP32). Common ground is key, learned that the hard way too.

Now, the Gate. This is the control pin. This is where the signal from my microcontroller goes. But here’s a little tip that saved me a lot of headaches: a pull-down resistor. I typically slap a 10k ohm resistor between the Gate pin and Ground. Why? Because without it, the Gate can sometimes float, picking up stray signals, and the MOSFET might turn on or off when you don’t want it to. It just makes things more predictable.

So, the microcontroller’s digital output pin connects to the Gate of the MOSFET. When my code sets that pin HIGH, the MOSFET turns on, and current flows through the motor from Drain to Source, making it spin. When I set the pin LOW, the MOSFET turns off, and the motor stops.

Testing and What I Learned

The first time I got it right, it was a proper “aha!” moment. The motor spun when I told it to, and the MOSFET didn’t turn into a tiny smoke machine. Success!

A few things I’ve picked up along the way:

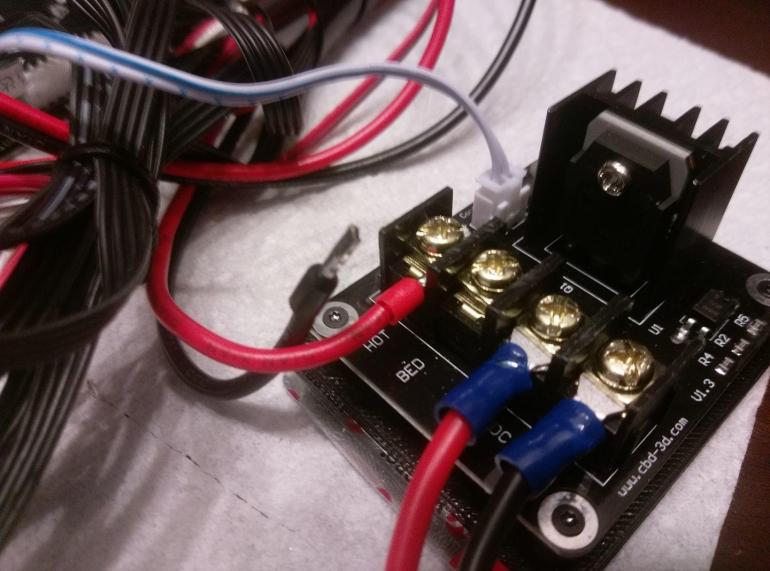

- Heatsinks are your friends. If you’re pushing a lot of current, these MOSFETs can get hot. A small heatsink can make a big difference in keeping them alive. I just bolt one on.

- Flyback diodes for inductive loads. If I’m controlling a motor or a solenoid (anything with a coil), I always put a flyback diode across the load (motor terminals). This protects the MOSFET from voltage spikes when the load turns off. Something like a 1N4007 usually does the trick for smaller stuff.

- Logic-level MOSFETs are easier with microcontrollers. Some MOSFETs need a higher voltage on the Gate to turn on fully, more than the 3.3V or 5V a microcontroller can provide. So, I try to get “logic-level” MOSFETs if I can. They’re designed to work nicely with microcontroller signal levels. If not, you might need a gate driver circuit, but that’s a whole other can of worms I try to avoid for simple projects.

So yeah, that’s my practical rundown of MOSFET wiring. It took some fumbling, a few fried components, but now it’s a pretty standard part of my toolkit for controlling things that need a bit more oomph. Hope my rambling helps someone out there avoid some of the same mistakes I made!