Alright, let’s talk about these MOSFET driver ICs. I remember when I first started messing around with beefier projects, you know, things that needed to switch some decent current. I naturally gravitated towards MOSFETs. Seemed simple enough: apply voltage to the gate, and it turns on. Easy peasy, right? Well, not quite, as I found out the hard way.

The First Headaches

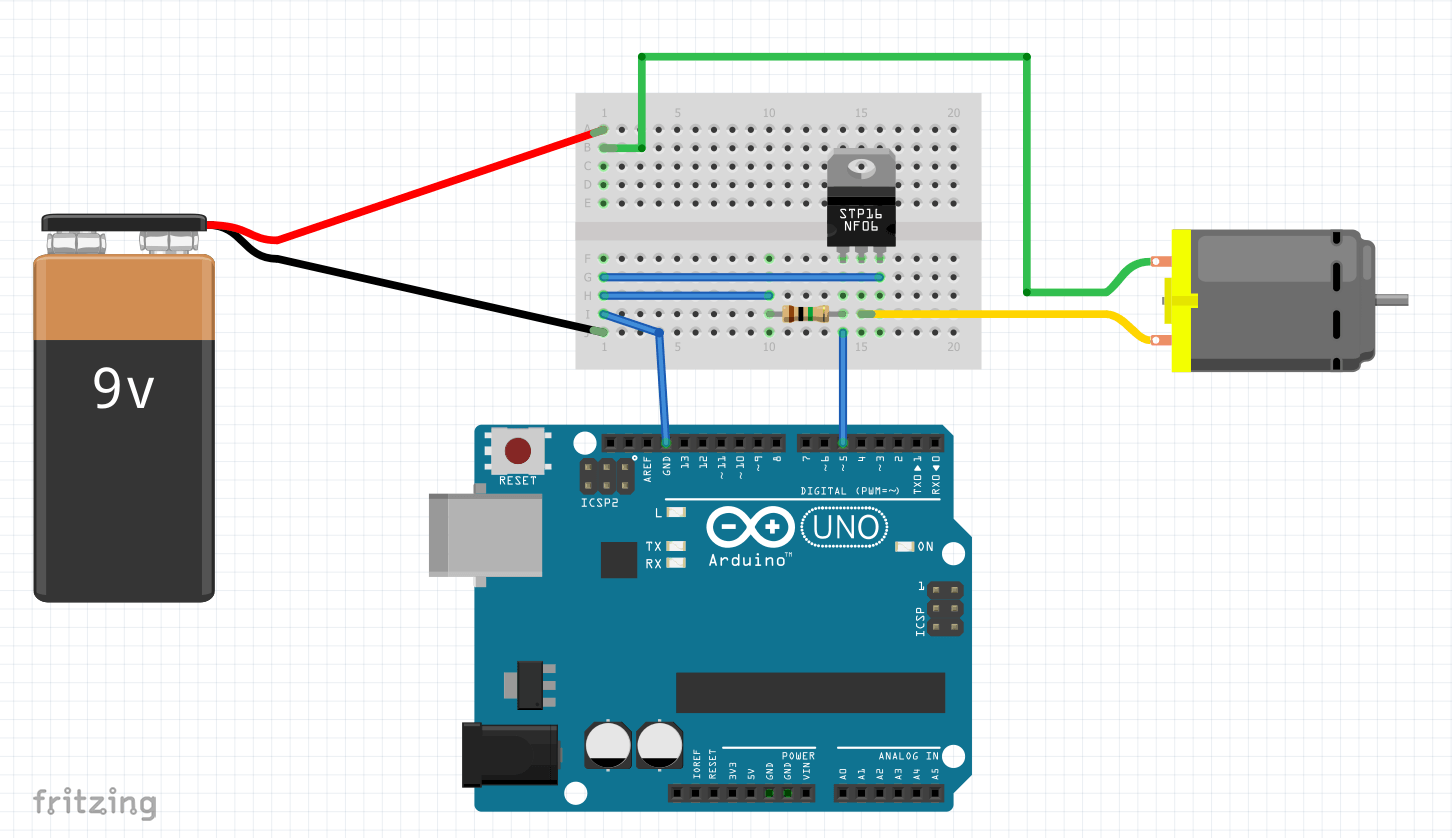

My initial setup was pretty straightforward. I was trying to control a motor, a fairly chunky one, using PWM from a microcontroller. So, I just hooked up a GPIO pin from my Arduino, or whatever little board I was using back then, directly to the MOSFET’s gate. I even put a pulldown resistor on the gate, feeling pretty clever about avoiding any floating states.

And then, the problems started. The MOSFET was getting surprisingly warm, even hot sometimes, especially when I tried to push the PWM frequency up. The switching wasn’t clean either. I hooked up my cheap oscilloscope – best investment ever, by the way – and the gate waveform looked, well, sad. It was slow to rise, slow to fall. It looked more like a shark fin than a square wave. My motor wasn’t happy, and neither was I.

Why Was It Failing?

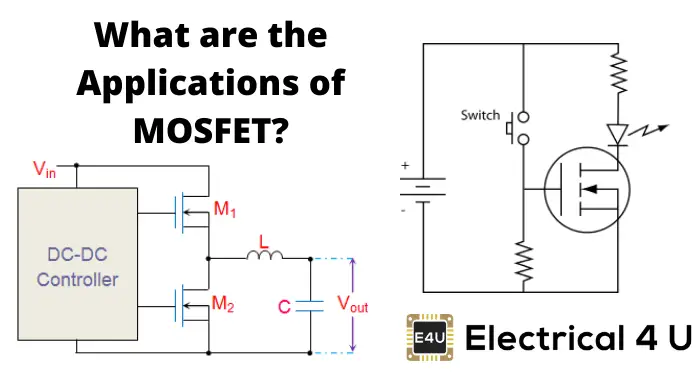

I spent a good amount of time scratching my head. I checked my code, my wiring, swapped out the MOSFET thinking maybe I had a dud. Nope. The issue, as I slowly started to realize after a lot of forum lurking and reading some application notes that felt like deciphering ancient texts, was all about driving that gate. A MOSFET gate, it turns out, acts like a capacitor. To turn the MOSFET on quickly, you need to charge that capacitor quickly. To turn it off quickly, you need to discharge it quickly. My little microcontroller pin, bless its heart, just couldn’t push or pull enough current to do that job effectively, especially not at the speeds I wanted.

It’s like trying to inflate a big car tire with a tiny bicycle pump. You’ll get there eventually, but it’s going to be slow and painful. And while the MOSFET is transitioning – not fully on, not fully off – it’s in a resistive state, and that’s when it dissipates power and gets hot. So, my slow switching was basically cooking the MOSFET.

Discovering the Driver IC

This is where the term “MOSFET driver IC” started popping up in my research. At first, I kind of dismissed them. “Another chip? More complexity?” I thought. I was trying to keep things simple. But the more I read, the more it seemed like this was the missing piece of the puzzle. These driver ICs are specifically designed to do one job: provide the hefty current pulses needed to charge and discharge the MOSFET gate capacitance rapidly.

So, I decided to give it a shot. I ordered a few common ones, I think it was something like a TC4427 or similar – just a basic low-side driver to get my feet wet. They weren’t even that expensive. When they arrived, I pulled up the datasheet. More hieroglyphs! But I waded through it. Power pins, input pin (from my microcontroller), output pin (to the MOSFET gate), and maybe an enable pin on some.

Wiring It Up and the “Aha!” Moment

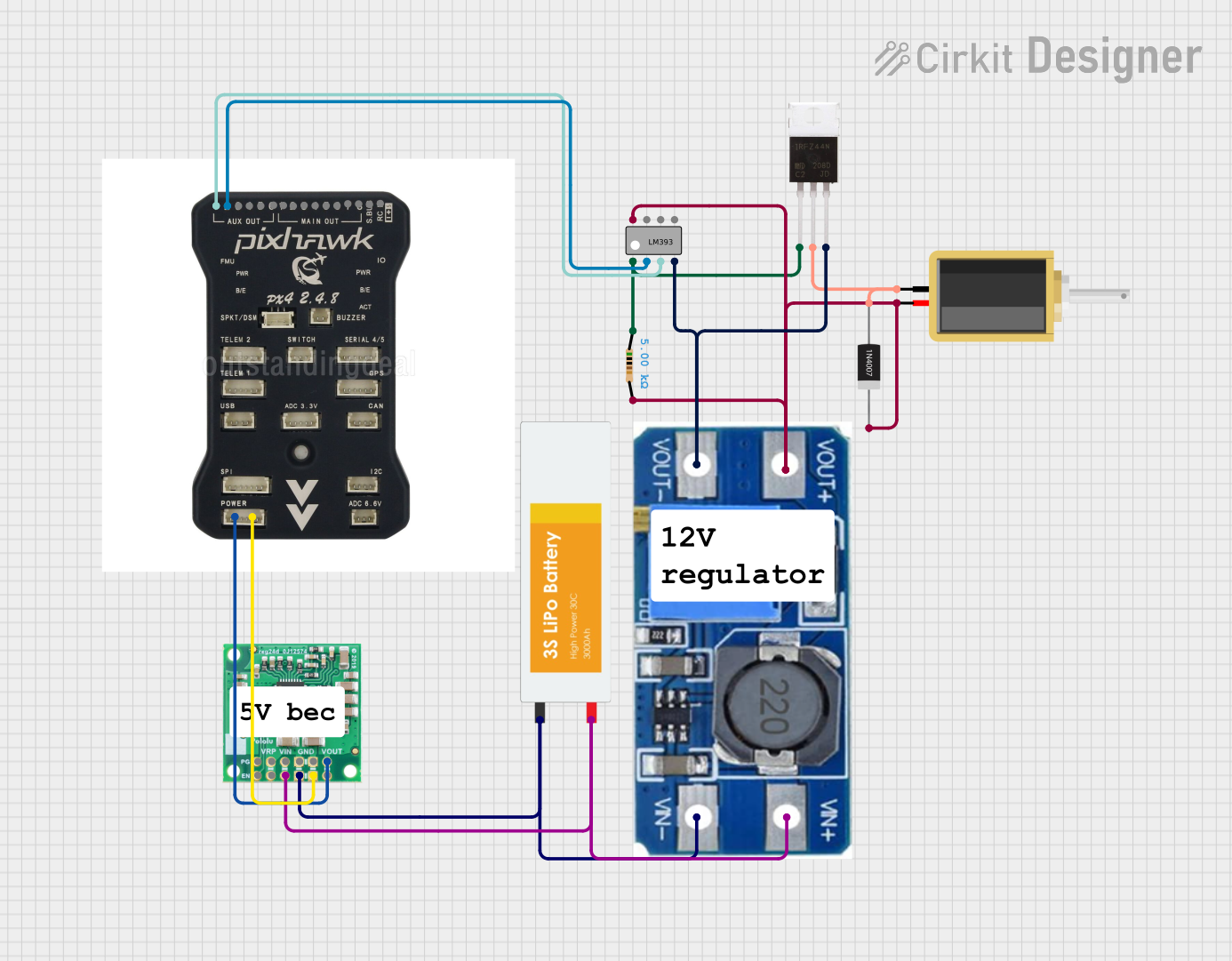

I breadboarded a new circuit. Microcontroller PWM output to the driver IC’s input. Driver IC’s output, through a small gate resistor (very important, I learned, to damp ringing), to the MOSFET’s gate. Connected the driver IC’s power supply, usually the same voltage as my logic or a bit higher if needed for the MOSFET. I was a bit nervous, always am when trying new power stuff. Double-checked everything.

Then, I powered it on and ran my PWM code. The difference was immediate and dramatic. Night and day!

- The MOSFET stayed cool. Like, barely warm to the touch.

- I scoped the gate again, and this time, the waveform was a thing of beauty. Sharp rising edge, sharp falling edge. Beautiful square waves.

- My motor responded crisply. The control felt much more precise.

It was one of those “aha!” moments. This little chip, which I’d initially ignored, made all the difference. It took the load off my microcontroller and did the heavy lifting of whacking that MOSFET gate with enough current to get it to switch properly.

What I Learned and Use Now

Since that first experience, MOSFET driver ICs have become a standard part of my toolkit whenever I’m working with power MOSFETs, especially for PWM applications or anything requiring fast switching. They’re not just a “nice to have”; in many cases, they’re essential for performance and reliability.

There’s a whole world of them too: low-side drivers, high-side drivers (which are more complex because the source of the MOSFET isn’t at ground), half-bridge drivers, full-bridge drivers. Each for different configurations. Learning about charge pumps and bootstrap capacitors for high-side driving was another adventure for another day!

So, if you’re out there struggling with hot MOSFETs or sluggish switching, and you’re trying to drive them directly from a microcontroller pin, do yourself a favor: look into MOSFET driver ICs. They can seem a bit daunting at first, but the improvement in performance is totally worth the small amount of extra circuitry. It’s a lesson I learned through a bit of frustration and smoke (okay, maybe not smoke, but definitely some overheating), and now it’s just standard practice for me.