Alright folks, so today finally decided to get off my butt and actually mess with MOSFET biasing for real this time. Kept hearing different things online about the “best” way, and frankly, it was confusing as heck. Needed to see for myself what actually works without burning stuff up.

The Plan & First Try (Fixed Resistor)

Grabbed my breadboard, a random N-channel MOSFET from the junk bin, a power supply, some resistors, and a load resistor. Started simple: fixed resistor bias. Like, really basic. Slapped a resistor between the gate and my positive rail. Figured it’d be easy. Hooked everything up, turned on the juice… and yeah, voltage at the drain was kinda stable. But man, when I swapped out that MOSFET for another one I found? Total chaos. Drain voltage jumped all over the place. Felt real dumb. This approach? Fine if you only ever use one exact same MOSFET forever in perfect weather. Otherwise? Pointless. Like trying to nail jello to a wall.

Second Attempt (Voltage Divider)

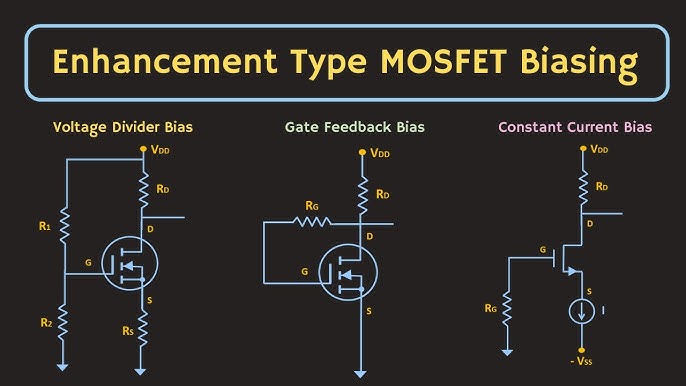

Okay, time for the classic voltage divider setup everyone talks about. Two resistors chained between positive and ground, gate tapped right in the middle. Sounded solid. Connected it all, twisted those resistor leads tight. Measured the gate voltage first – seemed nice and steady. Loaded it up, measured the drain. Better! Still changed a little when I heated up the MOSFET with my fingers (yeah, unscientific, but quick!), but way less drama than the fixed resistor mess. Way more predictable than before. Good ol’ voltage divider. Reliable workhorse. Doesn’t blow your mind, but gets the job done without burning the house down. Felt sensible.

Third Try (Current Source Biasing)

Felt a bit cocky after the divider worked, so I pulled out a small BJT transistor to rig up a simple current source for the gate. More parts now: BJT, another resistor. Breadboard getting crowded, messy wires everywhere. Set it so the current source fed the gate. Powered it up. Whoa. Drain voltage barely twitched when I swapped MOSFETs or when it got warm. Felt super stable, like locked in concrete. Pretty darn precise. But honestly? For just needing the MOSFET to switch a light or a motor, this felt like using a diamond-tipped drill to make a simple hole. Serious overkill unless you absolutely need that rock-solid stability, and you gotta add extra parts and complexity. Cool, but extra.

Wrapping Up & What Stuck

So what actually stuck? Fixed resistor? Forget it. Waste of time unless your project is disposable junk. The voltage divider? Honestly, it’s the sweet spot for probably 80% of what I’ll ever need. Predictable enough, stupid simple, cheap. Just works. Current source? Yeah, it rocks if you’re building something super precise where tiny drifts matter – maybe some sensitive analog thing or precision control. But for everyday stuff? Nah, too much hassle. My bench time today proved it: pick the tool that fits the job.